Helping you convert your dream product in to a reality

Indiaaditya Networks has been in the field of embedded development since the year 2004. Since then, we have worked with variety of industries, product verticals and market sectors. Indiaaditya Networks is primarily an Embedded Systems design and development company. Though we do other things like development of Desktop applications, and test equipment, Embedded development is and will remain our main forte.

The Services Provided:

We provide “END TO END” solution for electronic product development.

In the electronic product development, we undertake:

- Project Conceptualization

- Schematic Development

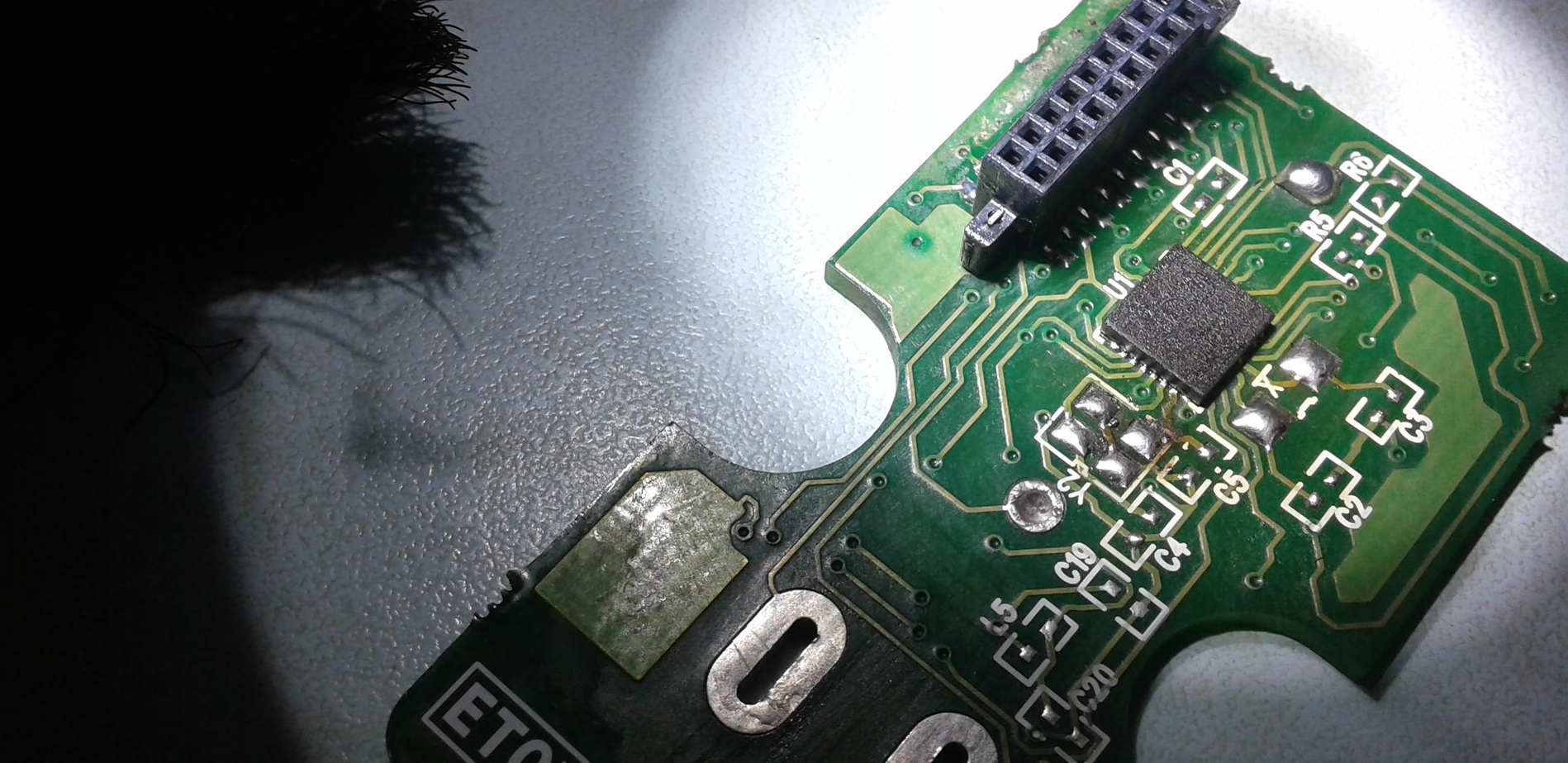

- PCB design and Implementation

- Board bring-up

- Firmware Development

- Integration and Testing

Essentially you share your concept with us and we will work with you to deliver a finished product. In addition to the above-mentioned steps, we also assist in bench-marking, developing the requirements, product life cycle planning, and component selection.

What sets us apart:

QUALITY

We cannot emphasize it enough. For us the quality of work is most important aspect. We follow following guidelines for implementations:

- Clean code implementation

- Modular code development

- Unit testing

- Right intentions

The code developed by us is scalable, well planned, structured, easy to read and maintainable.

Our Experience:

The controller Architectures:

We started working with the venerable 8051 microcontrollers and have till date worked with a variety of controllers from different manufacturers and architectures.

We have in-depth experience of working with ARM architecture and in this we have worked STM32, NxP, Nuvoton and Infineon controllers. In custom architectures we have worked with PIC series from Microchip and MSP430 series from TI.

The market verticals:

We have worked with the following sectors:

- Electrical Energy measurement, control and testing.

- Petrochemical, Refineries, and flow measurement sector

- Gas Industry

- Material Handling

- Consumer Goods Manufacturers

- Alternate fuels

- Medical field

- Automation

A comprehensive list of the work done can be found below.

The technology verticals:

- Ultra-low powered Designs: For products where Power/Energy budgeting is critical

- Digital Signal Processing: For high-speed complex computations. Complex FFT calculations, high speed RMS values and calculation of multiple parameters on the fly.

- Wireless: Detailed experience of working on various wireless technologies like BLE, Zigbee and RFID. This includes antenna design. Along with this we are working on Wi-Fi implementation on embedded controllers.

- Power Supply Designs: Development of Linear, Shunt and Switched Mode power supply designs. We develop multi-output, high efficiency, isolated supplies to satisfy the requirements of the product.

- Control Loop Implementations: Complex control loops implementations like PID, Sliding mode controls.

- Analog Circuit Designs and Integrations: Implementation of complex

- Communication: Implementation of various protocols on various physical layers. Eg: Modbus, Ethercat, CoE, CAN. We are in process of becoming a registered member of Ethercat group. Also implemented multiple custom communication protocols.

- Flame-proof and intrinsically safe designs: Designs for Zone-1 devices. Worked on three products with the certifying authorities.

- Embedded Linux: Implemented seven automation products based on Embedded Linux. Capabilities include Yocto and Device tree modifications, including implementation of multi-threaded implementations in C++.

A few of our distinguished customers:

- Cummins India

- Remote Technologies Inc., USA

- Cipla

- Welmade Locking Systems

- Tekno Valves

- Automatic Electricals

Assisting you in every step of your product development

Embedded Development involves multiple steps. We, at Indiaaditya Networks take pride in the fact that we provide complete solution for development needs of the customer to provide hassle free experience.

Conceptualize and Freezing of Specifications

Active involvement with customer to come up with the final specifications. This also involves bench-marking, future market requirement study and feasibility reports.

Project Roadmap

Guiding and assisting customer to manage the future prospects of the product by imbibing correct design solutions like selection and implementation from the very beginning.

Hardware Development

From component selection, co-ordination with mechanical design teams, Schematics Development, in-house PCB design, assembly, prototype manufacturing, board bring up and integration.

Power Supply Design

Design of power supplies. Complex linear power supplies, Switched mode Power supplies (along with magnetic selection), and Shunt regulators.

Firmware Development

Embedded C and C++ development is carried out with implementation of non blocking clean code which allows easy scalability and tight integrations. We give extreme importance to clean code implementation.

Testing and Qualification

Testing support for EMI/EMC, CE/UL Certifications, Flameproof and intrinsic safety standards. This includes making required modifications to the designs and communication with the testing authorities.

Industry Sectors and associated Products developed

Electrical Energy measurement, control and testing

High Voltage Tester: For measurement of breakdown voltage at a specified current limit. Completely programmable. Response time less than 10mSec.

Multi-Function Meter: Measurement of 56 different electrical parameters including Total Harmonic Distortion. Continuous measurement at 16 KHz and continuous calculations using the DSP of the STM32 micro-controller.

Petrochemical, Refineries, and flow measurement sector

Fuel Dispensing and Unloading Units: Fuel dispensing of multiple channels (main, Ethanol and additives) in proportion and mechanism selected by the user. Pressure and temperature compensation implemented. Flame-proof implementation with communication for full remote operation. Implemented multi-point calibration.

Flow/level Measurement Solutions: Interface of various flow meters for measurement of flow. Made multiple products for indicators and dispensers. Interfaced quadrature encoders also for flow direction, volume and rate. Also developed Battery powered totalizers with triplexed displays with battery life up to 10 years. Developed Hydro-static level measurement instruments for measurement with accuracy of upto 1mm. Unique analog design implemented.

Gas Industry

Coriollis Flow-meter Interface and dispensing control: Interfaced Endress+Hauser Coriolis flowmeter for complex unloading of gas or transfer to other containers.

Verification System for Pressure Release Devices (PRD) and Residual Pressure Valves (RPV): High speed testing of gas valves. System required testing at speeds which was beyond a standard PLC.

Material Handling

Manipulator Controllers: Implemented Pressure balancing using PID control and solenoid valves to replicate the operation of human motions.

Distributed control System for Mobile Rack Automation: RS-485 based control for automation of Mobile racks. Implemented variety of solutions in various forms for various customers.

Customized Load-cell interface: Implemented low cost high precision 4 load-cell interface for over weight detection of carousel system.

Consumer Goods

Electronic Lock Development: Developed Door Cupboard lock with stand-by current of 20uA. Interfacing bio-metrics like finger-print sensor and capacitance key pad.

Alternative Fuels

Furnace Controller: Developed completely automated Furnace controller for boiler plant for community kitchens where non-salable cotton waste is used as fuel. Using the temperature of water as a controlling parameter, the fuel being fed to the furnace was controlled.

Medical Field

Hyperbaric Oxygen Therapy: Mobile phone operated HBOT system where precise pressure control was required. The system also compensated for the leakages in the chamber. Precise pressure control up to second decimal place (in bars) using PID loop and high speed solenoid valves.

Infusion Pump Monitoring System: Multi-layered application. Data collection units developed to collect data from Infusion pumps over IRDA protocol and transfer it over BLE to a DTU (Data transfer unit). This unit collected data from the local devices and interfaced with AWS server to upload the data. Patient mapping was used which allowed the DTU to connect and disconnect from specific pump.

Automation

Servo Motor Ethercat Master Controller: For control of servo motor where Position, Velocity, Direction and Torque all have to be controlled precisely. Implemented Ethercat control of the master using SOEM open library. Implemented interfaces for Panasonic and Kollmorgen motors.

Temperature Bath: For monitoring the exact melting point for fusible alloy implemented camera controlled system using RPi and precise heating system using IGBT. Once the test is complete the user can run the video and find the exact instance of melting and generate report.

-

—

by